| Safetech Research Institute, SRI | |

|

Room 1702, 15F, Haitai Mansion, 229 North 4th Ring Road, Haidian District, Beijing, China |

|

| 100083 | |

| 010-56821118,56821119 | |

| www.ankosri.com | |

| Service@ankosri.com | |

|

|

CP Numerical Simulation Technology is an advanced method for CP optimizing design. It is the combination of computing simulation and modern CP technologies. Based on the protection potential and current density distribution which can be obtained, it is possible to conduct CP optimizing design and DC interference prediction and mitigation. This technique is a significant development direction of CP technologies, and showes advantage in the following application areas:

With the self-developed CP numerical simulation software system CPSOD, the internationally recognized BEASY CP software, the powerful simulation hardware system, and the experienced CP professionals, SRI can solve all kinds of complicated CP and interference technical problems with speed and quality, and thus conduct effect prediction, optimizing design and mitigation projects.

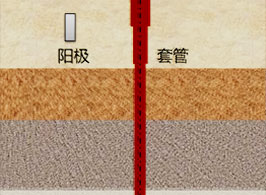

CP for Oil & Gas Well Case Pipe External Surface

As case pipes are usually spread as far as several kilometers, crossing different geographic structures, it is hard to evaluate the external CP effect for case pipes due to the difficulties in directly testing their protection potentials, let alone the shields and interference impact between several pipes. In this case, we can conduct on-site tests and inversion to obtain soil resistance and multi-layered soil models and to define the required current density. We can utilize the numerical simulation technology to complete the design and interference prediction and realize CP effect prediction and system optimization.

CP for External Anti-corrosion Layer of Long-distance Pipelines

Researches are focused on the new problems of long-distance transportation pipelines and their external anti-corrosion layers, and solutions are offered. Typical applications include CP design for seasonal frozen soil areas, parallel pipelines reasonable distance analysis, multiple pipeline shared CP analysis, flexible anode CP effect analysis for long-distance pipelines, CP and coating compatibility test and analysis, etc.

CP for Directional Drilling Crossing Sectors

The anti-corrosion layers of directional drilling crossing sectors are prone to damages, and CP potential cannot be tested directly. Therefore, corrosion and safety risks exist. Numerical simulation technology can solve the difficulties of test and evaluation.

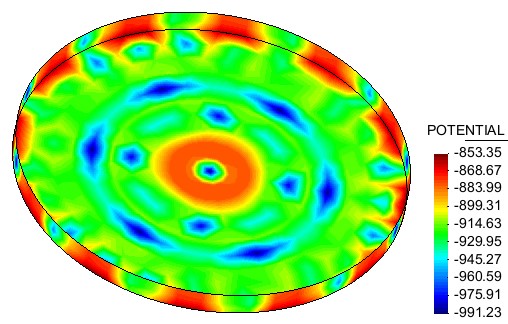

CP for Oil and Gas Station Area

Oil and Gas Station Areas have multiple protection objects, big impacts of grounding systems, severe interference and shield conditions, and limited spaces for anode earth bed design. Numerical simulation can provide adequate technological support for area CP optimization, by testing and numerical simulation analysis, predicting protection potential distribution, forecasting under-protection and over-protection areas, and defining anode earth bed optimizing layout.

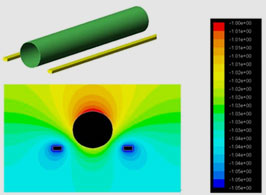

CP for Oil Storage Tank Bottom

As large tank bottom plate external surfaces have large protection areas, and the media of crude oil/water tank bottom internal surface have strong corrosivity and are in airtight spaces, traditional CP design effect cannot be ensured. In addition, it is hard to test the protection potentials and the afterward maintenance costs can be very high. Numerical simulation can predict the CP effect and optimize the design beforehand, taking into account the protection method, earth bed setting, anode type and quantity, setting method, etc.

o 3 Professors/Associate Professors, 4 Doctors, and several Masters and Bachelors, experienced in CP and AC/DC interference testing, assessment, design and research;

o NACE CP Certificate holders, including 3 CP4s, 2 CP3s, 2 CP2s;

o Offshore certificates and experience

TEL:010-82885770/5753-608/614nbsp;

TEL:010-82885770/5753-608/614nbsp;  E-mail:cpcrc@ankosri.com

E-mail:cpcrc@ankosri.com